Box-shaped pouches with five printable panels, excellent stability, and resealable options. Perfect for dry food, pet treats, coffee, and high-end SKUs. MOQ from 5,000 pcs.

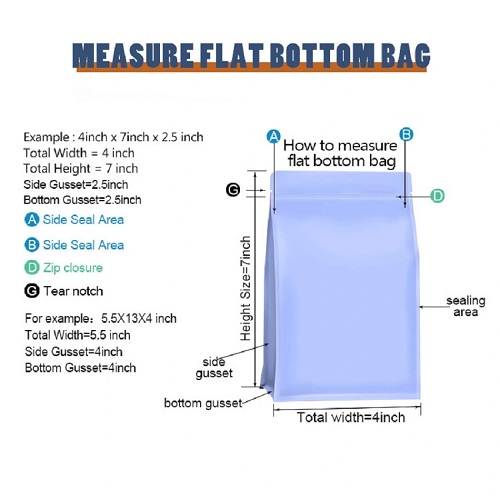

A flat bottom bag, also known as a block bottom bag, is a type of packaging that features a flat bottom and sides that expand to form a rectangular or square shape. This design allows the bag to stand upright on its own, making it ideal for products that need to be displayed on store shelves. Flat bottom bags are used in a wide range of industries, including food and beverage, pet food, and personal care products.

One of the key advantages of flat bottom bags is their versatility. They can be made from a variety of materials, such as paper, plastic, foil, and biodegradable materials, and can be printed with a range of designs and colors to create a unique look that appeals to customers. Flat bottom bags can also be fitted with various types of closures, such as zippers, tin-ties, or spouts, to provide easy access to the product inside and ensure freshness.

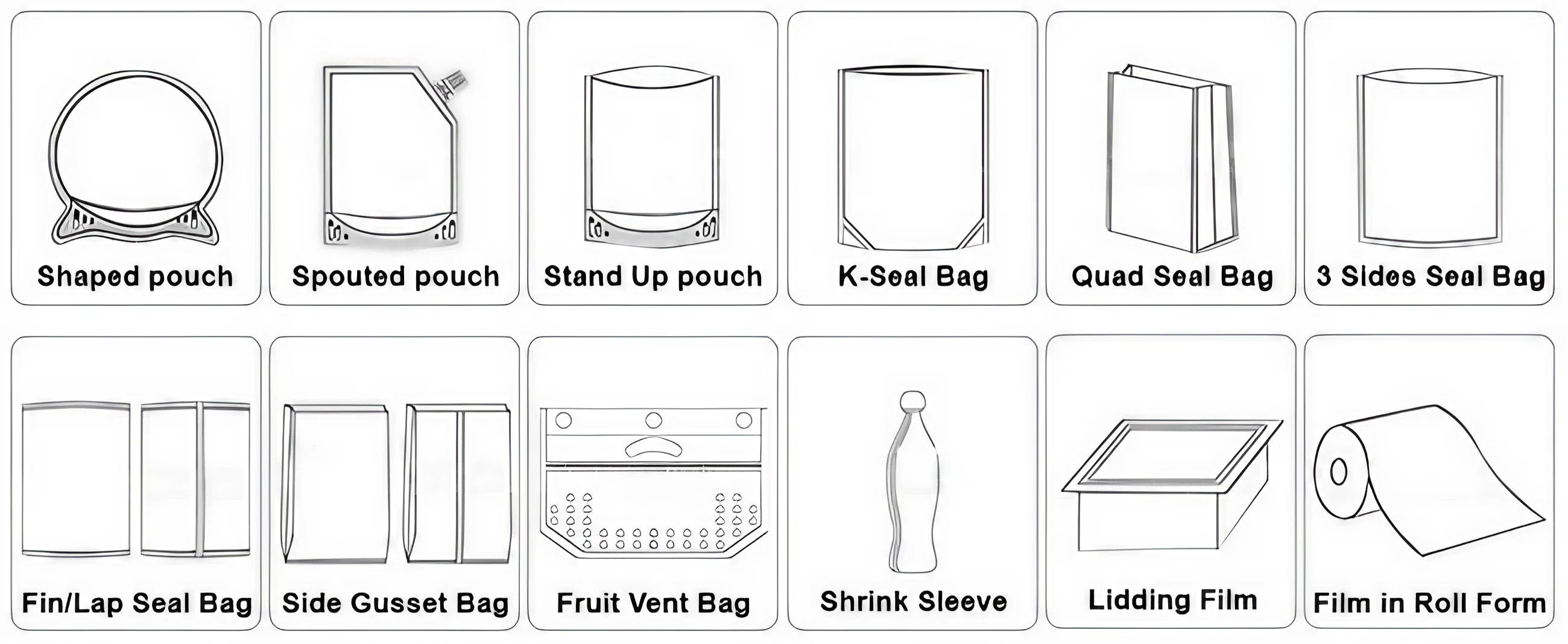

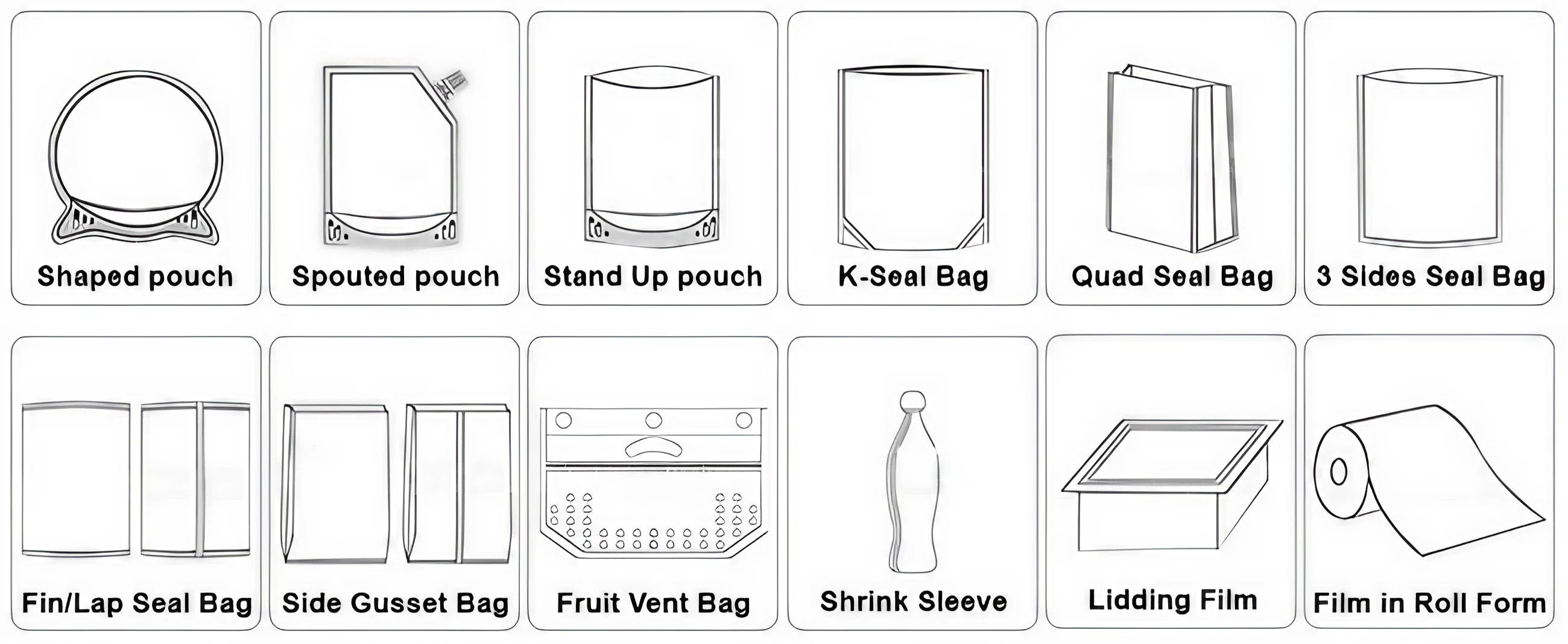

Application of Flat Bottom Bag

Flat bottom bags are versatile packaging solutions that can be used in various industries. Some of the common applications of flat bottom bags include:

Food packaging: Flat bottom bags are widely used in the food industry to package snacks, bakery products, confectionery, pet food, and other food items. The flat bottom design of the bag provides stability and allows the bag to stand upright on store shelves, making it easier to display the product.

Coffee and tea packaging: Flat bottom bags are ideal for packaging coffee and tea as they offer protection from moisture and air. The bags are usually made of laminated films that can preserve the aroma and flavor of the coffee or tea.

Pharmaceutical packaging: Flat bottom bags are also used in the pharmaceutical industry to package medicine and other healthcare products. The bags can be designed with child-resistant closures and tamper-evident features to ensure safety.

Pet food packaging: Flat bottom bags are also used in the pet food industry to package dry pet food. The bags are usually made of heavy-duty materials that can withstand the weight of the food and provide protection from moisture and air.

Cosmetics packaging: Flat bottom bags are increasingly used in the cosmetics industry to package various beauty products such as shampoos, lotions, and soaps. The bags can be designed with attractive graphics and custom branding to appeal to consumers.

Chemical packaging: Flat bottom bags are used in the chemical industry to package various chemicals, such as fertilizers, pesticides, and industrial chemicals. The bags can be designed with specialized features to ensure safety during transportation and storage.

Features of Flat Bottom Bag

Flat bottom bags have several features that make them popular in the packaging industry. Some of the key features of flat bottom bags include:

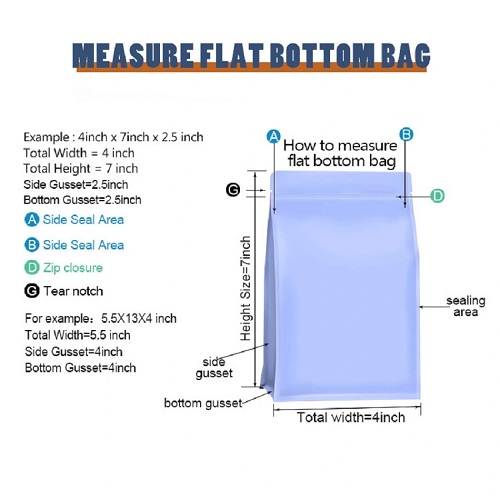

Flat bottom: As the name suggests, flat bottom bags have a flat base that allows them to stand upright on store shelves. This feature provides stability and makes it easier to display products.

Gusseted sides: Flat bottom bags have gusseted sides that expand when the bag is filled with product. This feature allows the bag to hold more product and provides more space for branding and product information.

Multiple layers: Flat bottom bags are made of multiple layers of materials, such as plastic, paper, or foil. These layers provide a barrier against moisture, light, and air, which helps to preserve the freshness and quality of the product.

Resealable closures: Many flat bottom bags come with resealable closures, such as zip locks or adhesive strips. These closures allow consumers to reseal the bag after use, which helps to keep the product fresh and prevents spills.

Custom printing: Flat bottom bags can be custom printed with branding, product information, and graphics. This feature allows companies to create a unique and attractive packaging design that helps to distinguish their product from competitors.

Recyclable and eco-friendly: Many flat bottom bags are made of recyclable materials, such as paper or biodegradable plastics. This feature makes them an eco-friendly packaging option that appeals to environmentally conscious consumers.

Films for flat bottom bags

There are several material structure options available for flat bottom bags, depending on your product's specific requirements, such as the product's weight, moisture resistance, and durability. Here are some common material structure options used in flat bottom bags:

Paper: Paper is a popular material for flat bottom bags because it is eco-friendly and biodegradable. It is suitable for dry products and can be coated with a moisture-resistant material to prevent moisture from penetrating the bag.

Plastic: Plastic is a versatile material that is commonly used in flat bottom bags. It is available in a variety of thicknesses and can be made with different properties, such as moisture resistance, puncture resistance, and UV resistance.

Foil: Foil is a material that is commonly used in flat bottom bags because of its barrier properties. It can prevent moisture, oxygen, and light from penetrating the bag, making it ideal for products that require a high level of protection.

Biodegradable materials: Biodegradable materials are becoming increasingly popular for flat bottom bags, as they offer an eco-friendly alternative to traditional plastics. Biodegradable materials can be made from a variety of sources, such as plant starch, and can be composted after use.

Laminated materials: Laminated materials are made by bonding two or more layers of material together. This can create a material that is more durable, moisture-resistant, and tear-resistant than a single-layer material.

Zipper Options for Flat Bottom Bags

There are several zipper options available for flat bottom bags, depending on your specific needs and preferences. Here are some common types of zippers used in flat bottom bags:

Press-to-close zipper: This is a simple, cost-effective zipper that is easy to use. It features a series of interlocking plastic teeth that can be pressed together to seal the bag.

Slider zipper: This type of zipper features a small tab or slider that is used to open and close the zipper. The slider moves up and down the length of the zipper to create a secure seal.

Airtight zipper: Airtight zippers are designed to create a completely airtight seal, making them ideal for packaging products that require a high level of protection from moisture or air.

Resealable zipper: This type of zipper allows the bag to be opened and closed multiple times, making it ideal for products that need to be accessed frequently.

Child-resistant zipper: Child-resistant zippers require a certain amount of pressure or dexterity to open, making them ideal for packaging products that are potentially dangerous or toxic.

Tamper-evident zipper: Tamper-evident zippers feature a seal that breaks if someone tries to open the bag, making it clear that the product has been tampered with.

We're With You From Idea to Executio

Solving big problems in unique ways is in our DNA. We do our best when we think holistically and come to market with a range of solutions that keep our environment in mind while making our customers’ lives easier.

Much like the packaging we manufacture, we are flexible in our ability to develop your ideal solution. Together, our technical sales team, packaging applications engineers, research and development team, and equipment engineers work to design a total packaging solution specifically suited to your product.

Packaging Applications Engineers

Conduct applications assessments and develop tailored packaging specifications to best protect and deliver your product.

Manage package validation process and protocols.

Troubleshoot quality issues and production opportunities in your facility.

Equipment Engineers

Design and build bag-in-box and pouch equipment to meet your unique packaging needs.

Perform factory acceptance testing and site acceptance testing and in-depth training for your production staff.

Field service maintenance available within hours of reported issues.

Research & Development

Work with you and your end-users to develop ideal film and fitment solutions.

In-house materials labs available for quality and interface testing so that you can be sure your product and our package solution works from day one.

Ongoing, dedicated support and analysis for any issue that may arise.

Technical Sales

Highly-trained sales team ready to work with you to determine the best package solution tailored for your product’s needs.

Coordinate customer interface with our Packaging Applications Engineers, Materials Lab, R&D Engineers, and Equipment Engineers to simplify your day.

Industry-leading manufacturing technology and design tool

We believe that any packaging opportunity can be met by applying knowledge and imagination. Our expert engineers and designers have a wealth of flexible packaging experience and can co-create innovative, functional and cost-effective solutions with you. Services include:

Compatibility, vibration, drop and shipment testing

CAD rendering models of parts and components

AutoDesk Moldflow simulation software

3D printing within 24 hours

MOCON oxygen transmission testing

Film, laminate and resin innovation

HoHui continues to lead the way in technological innovations and the design and manufacture of plastic packaging solutions. Through our manufacturing technologies we create custom packaging that successfully meets the most demanding filling and performance requirements while positioning our customers ahead of their competition.

Manufacturing Technologies utilize:

Industrial Design

HoHui's industry recognized, creative team collaborates with customers to quickly develop unique, manufacturable designs that meet new product needs and requirements.

Design solutions are developed rapidly because of our exceptional understanding of the balance between creative design, engineering and manufacturing.

Packaging Design

HoHui’s staff of Design Engineers sets the industry standard for product development including package design and performance. Whether it’s the development of a new design from scratch, optimization of a design developed by a third party or modifications/optimization to a package that’s currently commercial, HoHui’s team of Design Engineers works closely with our customers to deliver industry-leading engineered packaging solutions