Retortable, recyclable, zippered, spouted, and frozen-grade formats — all certified for food contact and production line compatible. MOQ from just 5,000 pcs.

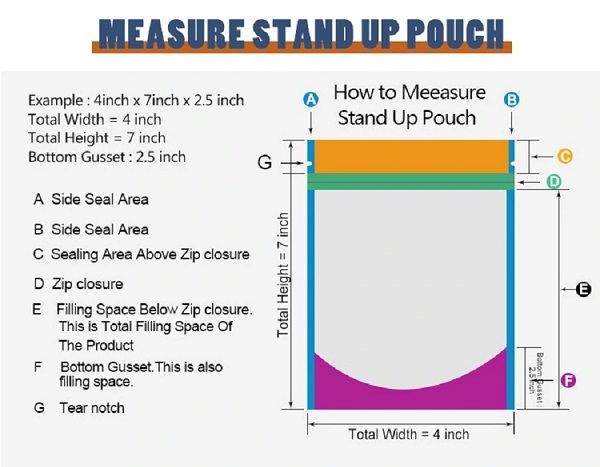

At Hohuiflex, we prioritize innovation and customization, tailoring our Stand Up Pouches to elevate your brand's unique identity. Our pouches feature resealable zippers, tear notches, and eco-conscious materials for a sustainable packaging choice that doesn't compromise on quality or aesthetics.

Partner with Hohuiflex for exceptional service, competitive pricing, and timely delivery. We're committed to customer satisfaction and fostering long-lasting relationships, offering expert guidance and support throughout your packaging journey.

Elevate your brand with Hohuiflex's Stand Up Pouches - the stylish, functional, and sustainable packaging solution designed to captivate and impress your customers.

Application of Stand Up Pouch

Stand-up pouches are a type of flexible packaging that can stand upright on their own due to their unique shape and design. These pouches have a wide range of applications across various industries, including food, beverage, pharmaceuticals, pet food, and personal care products. Some common uses of stand-up pouches include:

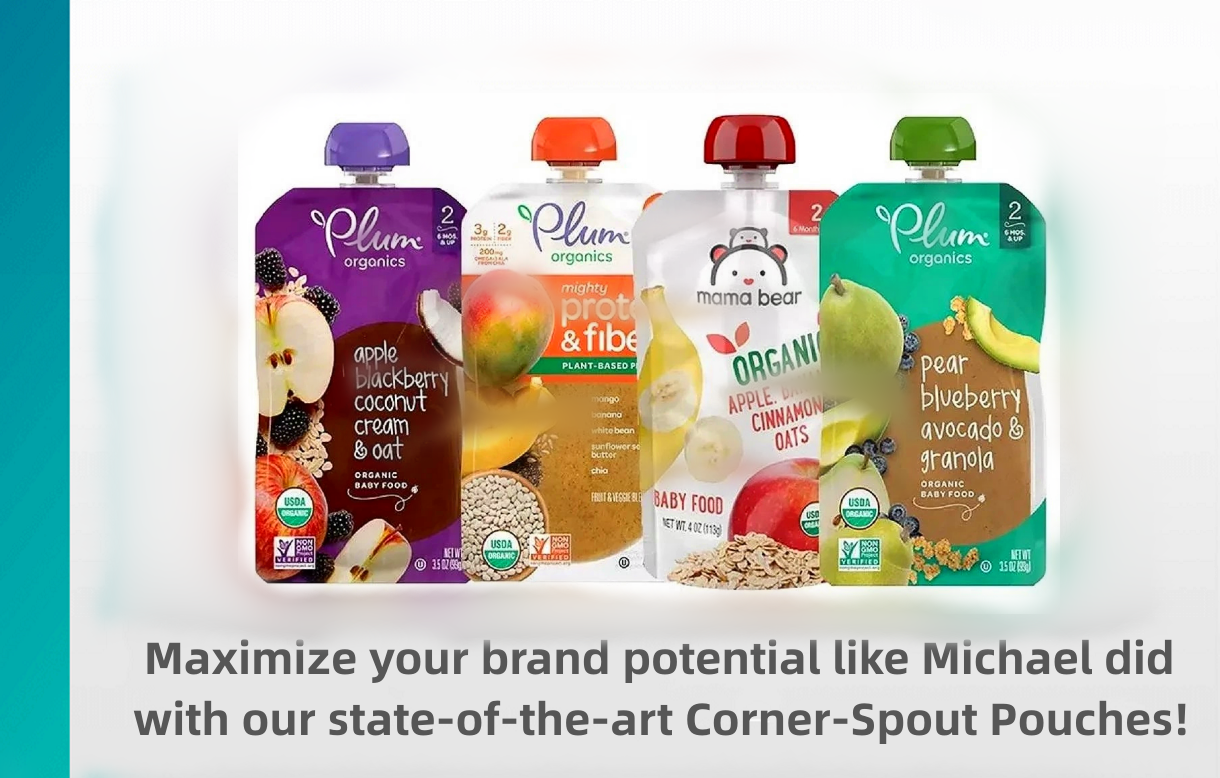

Food packaging: Stand-up pouches are commonly used for packaging food items such as coffee, tea, snacks, pet food, frozen food, and baby food. They provide excellent barrier properties, keeping the contents fresh and protected from moisture, oxygen, and light.

Beverage packaging: Stand-up pouches are also used for packaging various types of beverages, including juices, energy drinks, sports drinks, and water. These pouches offer a convenient and lightweight alternative to traditional rigid packaging options.

Pharmaceuticals and medical products: Stand-up pouches are used for packaging various pharmaceutical and medical products, including pills, powders, and liquid medications. They provide a safe and secure packaging option for these products, ensuring that they remain protected and free from contamination.

Personal care products: Stand-up pouches are used for packaging various personal care products, including shampoo, conditioner, lotions, and creams. These pouches provide a convenient and easy-to-use packaging option for these products, making them ideal for travel and on-the-go use.

Industrial products: Stand-up pouches are also used for packaging various industrial products, including chemicals, fertilizers, and other powders. They provide a safe and secure packaging option for these products, ensuring that they remain protected and free from contamination.

Advantages of Stand Up Pouch

Stand-up pouches offer several advantages over traditional packaging options, making them a popular choice across various industries. Here are some of the main advantages of stand-up pouches:

Excellent shelf appeal: Stand-up pouches offer excellent shelf appeal due to their unique shape and design, making them stand out on store shelves and attracting customers' attention.

Lightweight and easy to transport: Stand-up pouches are lightweight and take up less space than traditional packaging options, making them more cost-effective to transport and reducing the carbon footprint of shipping.

Versatile and customizable: Stand-up pouches can be made in a variety of sizes, shapes, and materials, allowing for customization to meet specific product needs. They can also be printed with high-quality graphics, text, and branding, providing excellent marketing opportunities.

Durable and protective: Stand-up pouches offer excellent barrier properties, protecting the contents from moisture, oxygen, and light. They also feature strong seals, preventing leakage and ensuring that the contents remain fresh.

Convenient and user-friendly: Stand-up pouches are easy to open, pour, and reseal, making them convenient for consumers to use and providing a more user-friendly packaging option.

Eco-friendly: Stand-up pouches are often made from recyclable materials, reducing waste and promoting sustainability.

Films for Stand Up Pouch

Stand-up pouches are flexible packaging solutions that are widely used in the food, beverage, and consumer goods industries. The material structure of a stand-up pouch plays a critical role in determining the pouch's overall performance, including its durability, barrier properties, and visual appeal. Here are some of the most common material structure options for stand-up pouches:

Polyethylene (PE) - PE is a type of plastic that is commonly used in stand-up pouches. It is a lightweight and flexible material that provides good barrier properties against moisture and oxygen.

Polypropylene (PP) - PP is another type of plastic that is commonly used in stand-up pouches. It provides excellent barrier properties against moisture, oxygen, and other gases.

PET/PE - PET/PE is a laminate material that consists of a layer of polyethylene bonded to a layer of polyester. It provides excellent barrier properties against moisture, oxygen, and other gases.

Nylon/PE - Nylon/PE is a laminate material that consists of a layer of nylon bonded to a layer of polyethylene. It provides excellent barrier properties against moisture, oxygen, and other gases, and it is also puncture-resistant.

Aluminum foil/PE - Aluminum foil/PE is a laminate material that consists of a layer of aluminum foil bonded to a layer of polyethylene. It provides excellent barrier properties against moisture, oxygen, and other gases, and it also provides good protection against light.

Paper/PE - Paper/PE is a laminate material that consists of a layer of paper bonded to a layer of polyethylene. It provides a natural look and feel to the pouch and can be printed with high-quality graphics.

Zipper for stand up pouch

Zipper options are an important consideration when choosing a stand-up pouch. The zipper provides a convenient and resealable closure for the pouch, allowing the contents to be accessed multiple times without compromising the freshness and quality of the product. Here are some of the most common zipper options for stand-up pouches:

Press-to-close zipper - This type of zipper is the most common option for stand-up pouches. It consists of two interlocking tracks that can be pressed together to seal the pouch. Press-to-close zippers are easy to use and provide a reliable seal.

Slider zipper - A slider zipper consists of a plastic track with a slider that can be moved up and down to open and close the pouch. Slider zippers provide a more secure seal than press-to-close zippers and are ideal for products that require a high level of protection.

Child-resistant zipper - A child-resistant zipper is designed to prevent young children from opening the pouch. It requires a specific combination of pressure and motion to open, making it difficult for children to access the contents. Child-resistant zippers are commonly used for products that are potentially harmful if ingested.

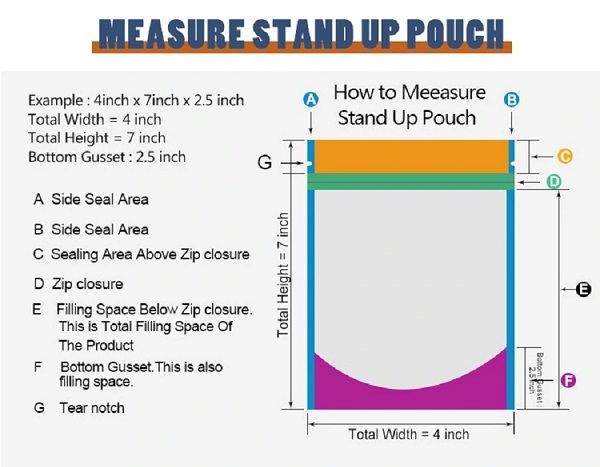

Tear notch - A tear notch is a small notch in the top of the pouch that can be torn off to open the pouch. It does not provide a resealable closure but is a cost-effective option for products that are not intended to be resealed.

Printing method for Stand-up pouch

Printing is a critical component of stand-up pouch design, as it enables brands to create high-quality graphics and text that showcase their products and communicate important information to consumers. Here are some of the most common printing method options for stand-up pouches:

Flexographic printing - Flexographic printing is a popular printing method for stand-up pouches. It uses flexible plates to transfer ink to the pouch material. Flexographic printing is ideal for high-volume runs and can produce high-quality graphics and text.

Rotogravure printing - Rotogravure printing is a high-speed printing method that uses engraved cylinders to transfer ink to the pouch material. It can produce very high-quality images and is often used for high-end products.

Digital printing - Digital printing is a modern printing method that uses digital files to print directly onto the pouch material. It is ideal for short runs and can produce high-quality graphics and text with a fast turnaround time.

Lithographic printing - Lithographic printing, also known as offset printing, is a high-quality printing method that uses a flat plate to transfer ink to the pouch material. It is ideal for high-quality images and can produce very fine details.

Gravure printing - Gravure printing is a type of printing that uses a metal cylinder with cells etched into its surface to transfer ink onto the pouch material. It can produce high-quality images and is often used for printing on metallic or glossy substrates.

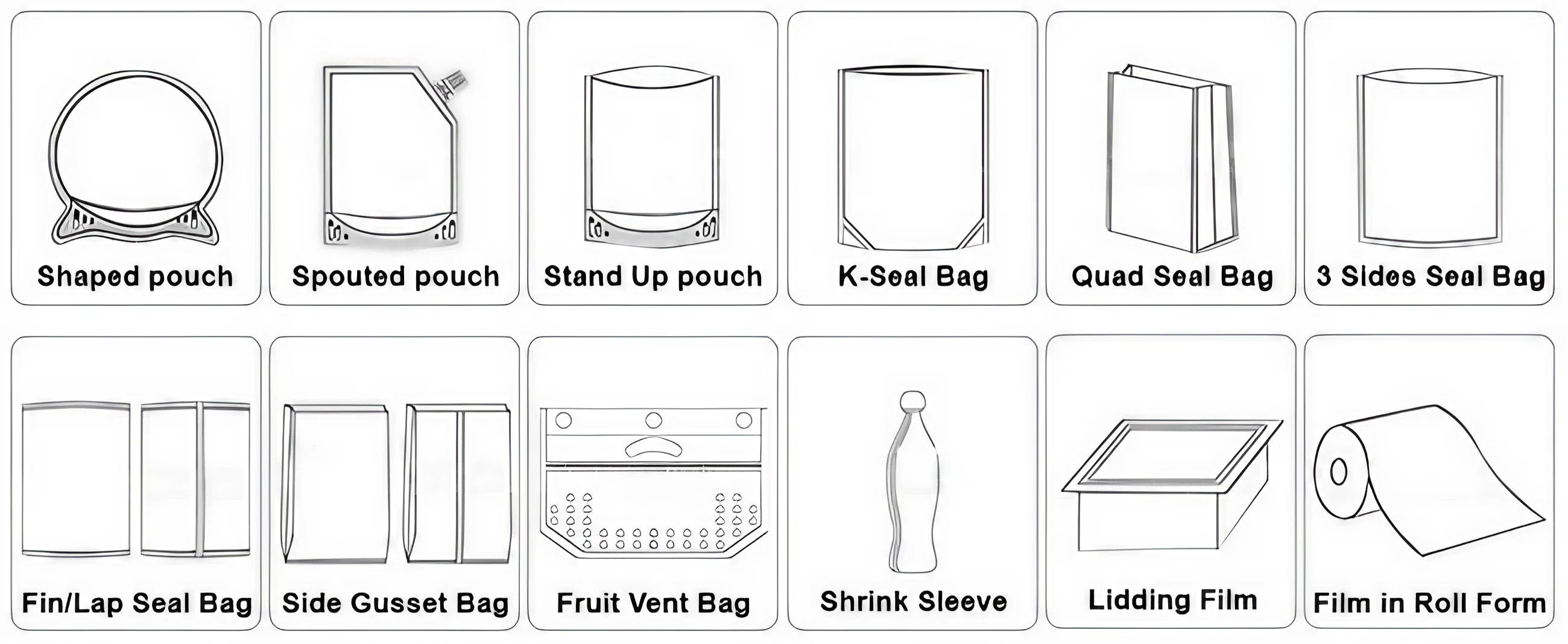

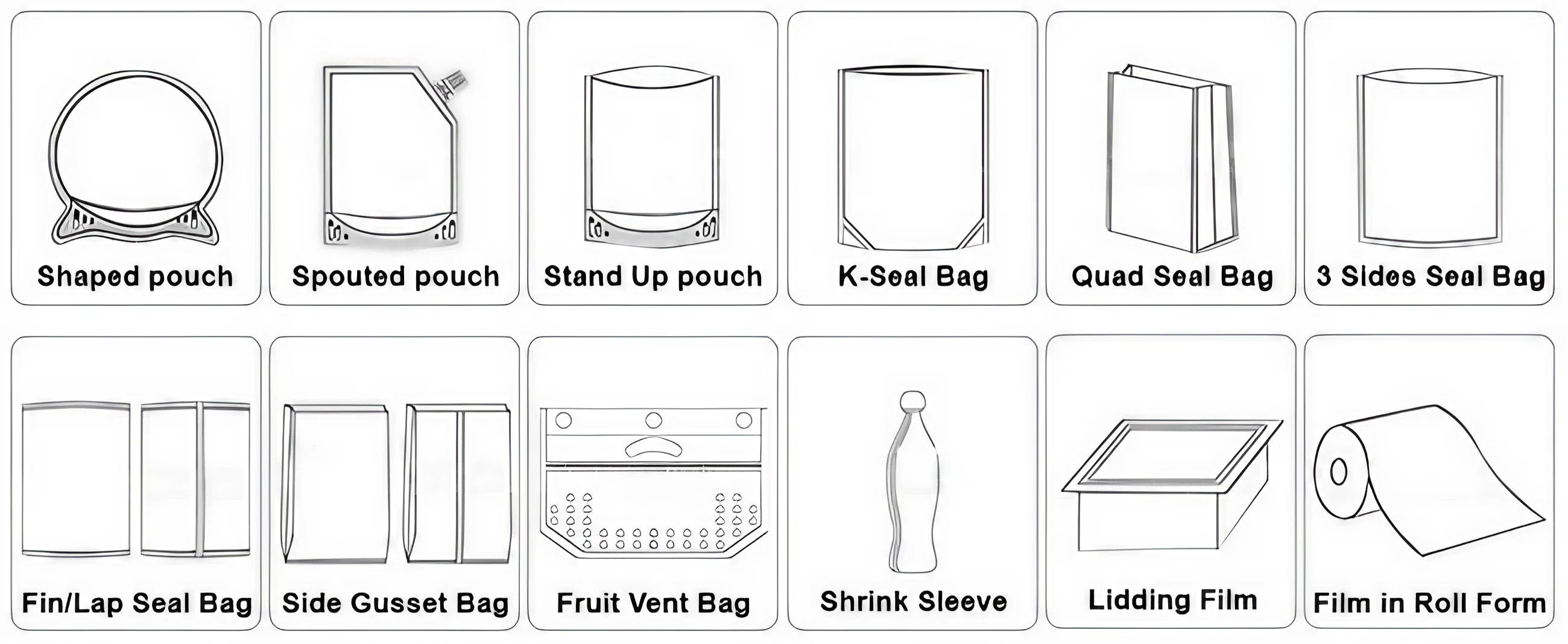

There are various bag shape options available for stand-up pouches, including:

01.Stand Up with Shaped Top Seal

02.Stand Up with Inclined Sides

03.Stand Up

04.Stand Up with Top Shape

05.Stand Up with Shaped Top Sides

06.Stand Up with Side Shape

07.Stand Up with Total Shape

08.Stand Up with Pouring Shape

09.Stand Up with Straw Inside

10.Stand Up with Laser Cut

11.Stand Up with Top Handle

12.Stand Up with Side Handle

13.Stand Up with Straw Outside

14.Stand Up with Reclosable Zipper

15.Stand Up with Jar Shape

Our Capability

We manufacture billions of pouches & label every year. Our clean room flexible packaging manufacturing environments are built for quality and product safety.

HohuiFlex features advanced rotogravure printing machines in 6, 9, and 12-color options. Each machine is outfitted with computerized color registration and online display systems, ensuring exceptional print quality at low film tension. These machines can handle various flexible and paper materials at high speeds, including select models with electronic axle printing at 200 meters per minute.

HohuiFlex operates 8 of the industry's most advanced blown film machines, including PA/PE 7 Layer Co-ex blown film machines, LDPE blown film machines, and LDPE two-color co-extrusion blown film machines. This diverse array of equipment enables us to quickly adjust production capacity and effectively control costs, meeting the ever-increasing demands of customer orders in terms of both capacity and cost.

HohuiFlex utilizes top-tier dry and extrusion laminators imported from Japan, designed for precision and high-quality lamination film production. Additionally, our European-imported solvent-less laminator offers an eco-friendly packaging solution. As a leader in the packaging industry, we continually invest in innovative technologies.

HoHuiFlex has acquired a comprehensive range of pouch manufacturing machines, zipper integration systems, and slitting devices from Japan & Germany. These machines enable the production of sachets and bags with built-in, easy-to-open features using an automated process. Our facilities are fully equipped to meet the diverse pouch requirements of our multinational clients.These advanced pouch-making machines can produce a wide range of bag styles, such as three-side seal pouches with or without zippers, stand-up pouches with reinforced bottoms, four-sided fin sealed bags for optimal product protection, flat-bottom bags for enhanced stability, special-shaped pouches for unique products, and customizable hang hole and tear notch options for consumer convenience.

Industry-leading manufacturing technology and design tool

We believe that any packaging opportunity can be met by applying knowledge and imagination. Our expert engineers and designers have a wealth of flexible packaging experience and can co-create innovative, functional and cost-effective solutions with you. Services include:

Compatibility, vibration, drop and shipment testing

CAD rendering models of parts and components

AutoDesk Moldflow simulation software

3D printing within 24 hours

MOCON oxygen transmission testing

Film, laminate and resin innovation

HoHui continues to lead the way in technological innovations and the design and manufacture of plastic packaging solutions. Through our manufacturing technologies we create custom packaging that successfully meets the most demanding filling and performance requirements while positioning our customers ahead of their competition.

Manufacturing Technologies utilize:

Industrial Design

HoHui's industry recognized, creative team collaborates with customers to quickly develop unique, manufacturable designs that meet new product needs and requirements.

Design solutions are developed rapidly because of our exceptional understanding of the balance between creative design, engineering and manufacturing.

Packaging Design

HoHui’s staff of Design Engineers sets the industry standard for product development including package design and performance. Whether it’s the development of a new design from scratch, optimization of a design developed by a third party or modifications/optimization to a package that’s currently commercial, HoHui’s team of Design Engineers works closely with our customers to deliver industry-leading engineered packaging solutions

01.Stand Up with Shaped Top Seal

01.Stand Up with Shaped Top Seal 02.Stand Up with Inclined Sides

02.Stand Up with Inclined Sides 03.Stand Up

03.Stand Up 04.Stand Up with Top Shape

04.Stand Up with Top Shape 05.Stand Up with Shaped Top Sides

05.Stand Up with Shaped Top Sides 06.Stand Up with Side Shape

06.Stand Up with Side Shape 07.Stand Up with Total Shape

07.Stand Up with Total Shape 08.Stand Up with Pouring Shape

08.Stand Up with Pouring Shape 09.Stand Up with Straw Inside

09.Stand Up with Straw Inside 10.Stand Up with Laser Cut

10.Stand Up with Laser Cut 11.Stand Up with Top Handle

11.Stand Up with Top Handle 12.Stand Up with Side Handle

12.Stand Up with Side Handle 13.Stand Up with Straw Outside

13.Stand Up with Straw Outside 14.Stand Up with Reclosable Zipper

14.Stand Up with Reclosable Zipper 15.Stand Up with Jar Shape

15.Stand Up with Jar Shape