Oven-Safe Bags for Retail-Ready, Heat-and-Serve Meals, Bake-in, roast-in, and go-to-market faster.

Ovenable bags engineered for frozen meals, roast kits, ready-to-cook proteins, and bakery items. Heat-seal safe, up to 220°C. MOQ from 5,000 pcs. Samples in 7 days.

Features of Ovenable Bags

Ovenable bags, also known as oven bags or roasting bags, are a convenient and effective way to cook various types of food in the oven. They provide numerous benefits to the cooking process, including easier cleanup and more even cooking. Here are some key features of ovenable bags:

Heat-resistant material: Ovenable bags are made from heat-resistant materials like polyester or nylon, which can withstand high temperatures (up to 400°F/200°C) without melting or breaking down.

Food-safe: These bags are designed to be food-safe and are free of harmful chemicals like BPA, phthalates, and dioxins. This ensures that no toxic substances will leach into your food during the cooking process.

Size variety: Ovenable bags are available in various sizes to accommodate different types and quantities of food. Some common sizes include small, medium, large, and extra-large, suitable for everything from individual portions to entire turkeys.

Transparent: The bags are typically transparent or semi-transparent, allowing you to easily monitor the cooking process without opening the oven door.

Self-basting: Ovenable bags can help to keep food moist by trapping steam and juices inside the bag. This self-basting process reduces the need for added fats or oils and can result in healthier, more flavorful dishes.

Easy cleanup: Using an ovenable bag can significantly cut down on cleanup time, as it prevents spills and splatters inside the oven. After cooking, simply dispose of the bag, and your oven will remain clean.

Versatile: Ovenable bags can be used for various types of food, including meat, poultry, fish, vegetables, and even desserts. They are suitable for roasting, baking, and steaming.

Microwave-safe: Many ovenable bags are also safe for use in the microwave, providing an additional method for cooking or reheating food.

Cooking time reduction: Due to the trapped heat and steam, ovenable bags can help to reduce cooking times, often resulting in faster, more efficient cooking.

Easy sealing: Ovenable bags usually come with a closure system, such as ties or a self-adhesive strip, to help seal the bag and keep the contents contained during cooking. This helps to maintain the bag's integrity and prevent leaks.

Recipe-friendly: Many ovenable bag brands provide recipes or cooking instructions specifically designed for use with their bags, making it easy for users to get started and achieve successful results.

how to use ovenable bags:

Preheat the oven: Preheat your oven to the appropriate temperature as per the recipe or package instructions. Keep in mind that ovenable bags are typically suitable for temperatures up to 400°F (204°C). Avoid using them at higher temperatures, as they may melt or release harmful chemicals.

Choose the right size bag: Select an ovenable bag that is large enough to accommodate your food item, with extra room for the bag to expand as it traps steam during cooking.

Prepare the food: Season or marinate your food as desired. You can add herbs, spices, or other flavorings directly to the bag. For poultry, make sure to remove giblets before cooking.

Add a tablespoon of flour: Before placing the food into the bag, add about one tablespoon of all-purpose flour. Close the bag and shake it gently to coat the inside of the bag. This helps prevent the bag from bursting and reduces the likelihood of the food sticking to the bag.

Load the food into the bag: Place the food inside the ovenable bag, arranging it evenly. If you're cooking vegetables or other side dishes, you can add them alongside the main dish in the bag.

Seal the bag: Use the provided nylon tie or a heat-resistant clip to seal the bag securely. Make sure there are no leaks or open areas in the bag.

Vent the bag: To allow steam to escape, use a sharp knife or scissors to make a few small slits (about 1/2 inch) on the top of the bag.

Place the bag in a baking dish: Transfer the sealed and vented ovenable bag to a baking dish, ensuring that the food is in a single layer. The dish should be deep enough to catch any drippings that may leak from the bag. Keep the bag away from direct contact with heating elements or oven walls.

Cook the food: Place the baking dish with the ovenable bag in the preheated oven, following the cooking time and temperature guidelines provided by the recipe or package instructions. Check for doneness using a meat thermometer or visual cues, such as browning and bubbling.

Remove from the oven: When the food is fully cooked, carefully remove the baking dish from the oven using oven mitts, as the bag and its contents will be hot. Let the bag rest for a few minutes to allow steam to escape and the food to settle.

Open the bag: Using scissors, carefully cut open the top of the ovenable bag, being cautious of the hot steam that may escape. Be careful not to spill any juices or contents.

Serve and enjoy: Transfer the cooked food to a serving dish and enjoy your delicious meal. Discard the used ovenable bag, as they are not reusable.

Our Capability

We manufacture billions of pouches & label every year. Our clean room flexible packaging manufacturing environments are built for quality and product safety.

HohuiFlex features advanced rotogravure printing machines in 6, 9, and 12-color options. Each machine is outfitted with computerized color registration and online display systems, ensuring exceptional print quality at low film tension. These machines can handle various flexible and paper materials at high speeds, including select models with electronic axle printing at 200 meters per minute.

HohuiFlex operates 8 of the industry's most advanced blown film machines, including PA/PE 7 Layer Co-ex blown film machines, LDPE blown film machines, and LDPE two-color co-extrusion blown film machines. This diverse array of equipment enables us to quickly adjust production capacity and effectively control costs, meeting the ever-increasing demands of customer orders in terms of both capacity and cost.

HohuiFlex utilizes top-tier dry and extrusion laminators imported from Japan, designed for precision and high-quality lamination film production. Additionally, our European-imported solvent-less laminator offers an eco-friendly packaging solution. As a leader in the packaging industry, we continually invest in innovative technologies.

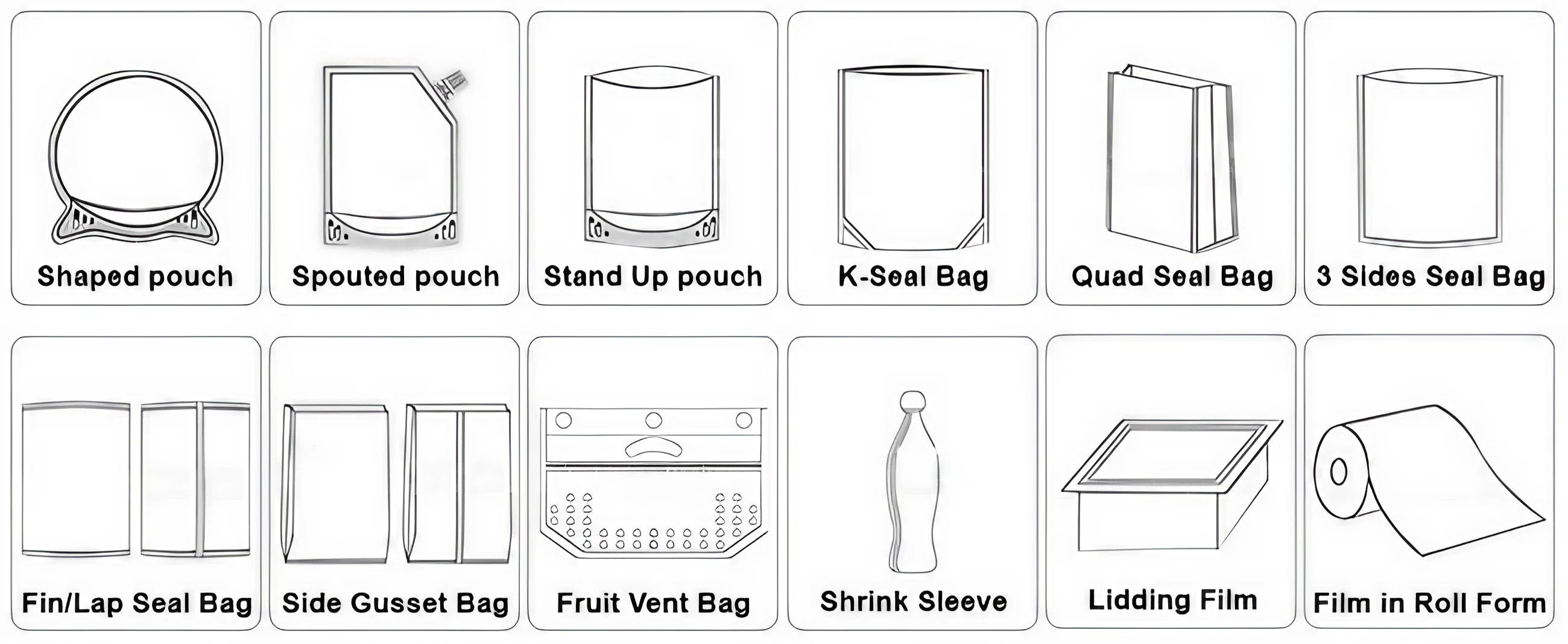

HoHuiFlex has acquired a comprehensive range of pouch manufacturing machines, zipper integration systems, and slitting devices from Japan & Germany. These machines enable the production of sachets and bags with built-in, easy-to-open features using an automated process. Our facilities are fully equipped to meet the diverse pouch requirements of our multinational clients.These advanced pouch-making machines can produce a wide range of bag styles, such as three-side seal pouches with or without zippers, stand-up pouches with reinforced bottoms, four-sided fin sealed bags for optimal product protection, flat-bottom bags for enhanced stability, special-shaped pouches for unique products, and customizable hang hole and tear notch options for consumer convenience.

Industry-leading manufacturing technology and design tool

We believe that any packaging opportunity can be met by applying knowledge and imagination. Our expert engineers and designers have a wealth of flexible packaging experience and can co-create innovative, functional and cost-effective solutions with you. Services include:

Compatibility, vibration, drop and shipment testing

CAD rendering models of parts and components

AutoDesk Moldflow simulation software

3D printing within 24 hours

MOCON oxygen transmission testing

Film, laminate and resin innovation

HoHui continues to lead the way in technological innovations and the design and manufacture of plastic packaging solutions. Through our manufacturing technologies we create custom packaging that successfully meets the most demanding filling and performance requirements while positioning our customers ahead of their competition.

Manufacturing Technologies utilize:

Industrial Design

HoHui's industry recognized, creative team collaborates with customers to quickly develop unique, manufacturable designs that meet new product needs and requirements.

Design solutions are developed rapidly because of our exceptional understanding of the balance between creative design, engineering and manufacturing.

Packaging Design

HoHui’s staff of Design Engineers sets the industry standard for product development including package design and performance. Whether it’s the development of a new design from scratch, optimization of a design developed by a third party or modifications/optimization to a package that’s currently commercial, HoHui’s team of Design Engineers works closely with our customers to deliver industry-leading engineered packaging solutions