Ziplock Bags for Food, Retail & eCommerce SKUs, Clean reseal. Certified barrier. Built to last — and reclose.

High-barrier ziplock bags for snacks, apparel, beauty, and supplements. Custom sizes, printable, recyclable structures available. MOQ from 5,000 pcs. Samples in 7 days.

Application of LDPE Double Zipper Bags

Low-Density Polyethylene (LDPE) double zipper bags are versatile and widely used for various applications due to their durability, flexibility, and affordability. These bags offer a secure double zipper closure system that ensures the contents inside remain fresh and protected. Here, we'll discuss some of the key applications of LDPE double zipper bags and their benefits.

Food Storage and Preservation:LDPE double zipper bags are ideal for storing and preserving various food items such as fruits, vegetables, meat, and snacks. The airtight seal helps maintain freshness, prevents odors from escaping, and safeguards against contamination. These bags are also suitable for storing dry goods such as grains, cereals, and spices.

Freezing:LDPE bags are suitable for freezing food items, as they can withstand low temperatures without becoming brittle or losing their flexibility. The double zipper seal helps prevent freezer burn and the formation of ice crystals, preserving the quality and taste of the food.

Organization and Storage:These bags are perfect for organizing and storing small items such as toys, stationery, sewing supplies, and electronic accessories. The transparent material allows for easy identification of contents, while the double zipper ensures items remain secure and dust-free.

Travel and Toiletries:LDPE double zipper bags are ideal for organizing and storing toiletries during travel. They can hold items like toothbrushes, razors, soap bars, and travel-sized bottles, preventing leakage and keeping everything in one place.

Packing and Shipping:These bags can be used to pack and ship small items such as jewelry, electronic components, or other delicate objects. The airtight seal keeps dust and dirt out, while the bag's flexibility offers some protection against impact and damage during transit.

Gardening and Agriculture:LDPE double zipper bags can be used to store seeds, bulbs, and plant cuttings. The airtight seal maintains moisture levels and keeps pests away, ensuring optimal conditions for germination and growth.

Medical and Pharmaceutical:In medical and pharmaceutical settings, these bags are often used for storing and organizing medical supplies, equipment, and medications. The double zipper closure helps maintain sterility and prevent contamination.

Laboratory and Research:LDPE bags are commonly used in laboratories and research facilities for storing and transporting samples, chemicals, and biological materials. The airtight seal protects against contamination and maintains sample integrity.

Feature of LDPE Double Zipper Bags

Low-Density Polyethylene (LDPE) double zipper bags have several features that make them an excellent choice for various applications across multiple industries. Below are some key features of these bags:

Double Zipper Closure:The double zipper closure system provides an airtight seal, ensuring the contents inside remain fresh and secure. This feature is particularly useful for food storage and preservation, as it prevents contamination and the escape of odors.

Durability and Flexibility:LDPE bags are known for their durability and flexibility. They can withstand rough handling, resist tearing, and maintain their shape even when subjected to varying temperatures. This makes them suitable for diverse applications, including freezing and shipping.

Lightweight:LDPE double zipper bags are lightweight, making them easy to handle and transport. This feature is particularly beneficial when it comes to shipping, as it helps reduce shipping costs.

Transparency:The transparent nature of LDPE bags allows for easy identification of contents without opening the bag. This feature is helpful for organizing and storing items, as well as for quality control and inspection purposes.

Moisture and Dust Resistance:The airtight seal created by the double zipper closure helps keep moisture and dust out, protecting the contents inside from damage and contamination.

Chemical Resistance:LDPE bags have good resistance to many chemicals, making them suitable for storing and transporting various substances, including laboratory samples and chemicals.

Customizable Sizes and Thicknesses:LDPE double zipper bags are available in a wide range of sizes and thicknesses to accommodate different needs and applications. This versatility allows users to choose the most suitable bag for their specific requirements.

Food-Safe and Recyclable Material:LDPE is a food-safe material, which means it is safe for storing and preserving food items. Additionally, LDPE is recyclable, making these bags an environmentally friendly option.

Cost-Effective:LDPE double zipper bags are an affordable solution for various storage and packaging needs, making them a popular choice for both commercial and residential use.

Zipper Options for LDPE Zipper Freezer Bags

Low-Density Polyethylene (LDPE) double zipper bags offer a secure and reliable closure system. In addition to the standard double zipper closure, there are several other zipper options available that cater to different needs and preferences. Some of these options include:

Slider Zipper:The slider zipper features a small plastic or metal slider that moves along the zipper track, making it easy to open and close the bag. This type of zipper provides convenience and ease of use, especially for people with limited dexterity.

Color-Coded Zippers:Color-coded zippers can help differentiate between bags containing different items or used for different purposes. For example, red zippers could be used for raw meats, while green zippers could be used for vegetables. This feature adds an organizational aspect to LDPE double zipper bags, making it easier to locate specific items.

Tamper-Evident Zippers:Tamper-evident zippers are designed to show evidence of tampering or unauthorized access. These zippers are particularly useful for sensitive materials, such as legal documents, pharmaceutical products, or valuable items. Once the tamper-evident seal is broken, it cannot be resealed, indicating that the contents may have been compromised.

Child-Resistant Zippers:Child-resistant zippers require a specific technique or force to open, making it difficult for young children to access the contents. This zipper option is particularly beneficial for bags containing potentially hazardous materials, such as medications, cleaning products, or small parts that could pose a choking hazard.

Heavy-Duty Zippers:Heavy-duty zippers are designed to withstand more rigorous use and provide extra strength for heavier contents. These zippers are suitable for applications where durability and security are essential, such as in industrial or construction settings.

Reclosable Zippers with Tear Notches:These zippers feature tear notches at the top of the bag, allowing users to easily tear open the bag without the need for scissors or other cutting tools. Once opened, the bag can be resealed using the zipper closure, maintaining the freshness and security of the contents.

Press-to-Close Zippers:Press-to-close zippers, also known as pinch-and-seal zippers, require users to press the two sides of the zipper together to create an airtight seal. These zippers offer a simple and efficient closure system, suitable for various applications.

Our Capability

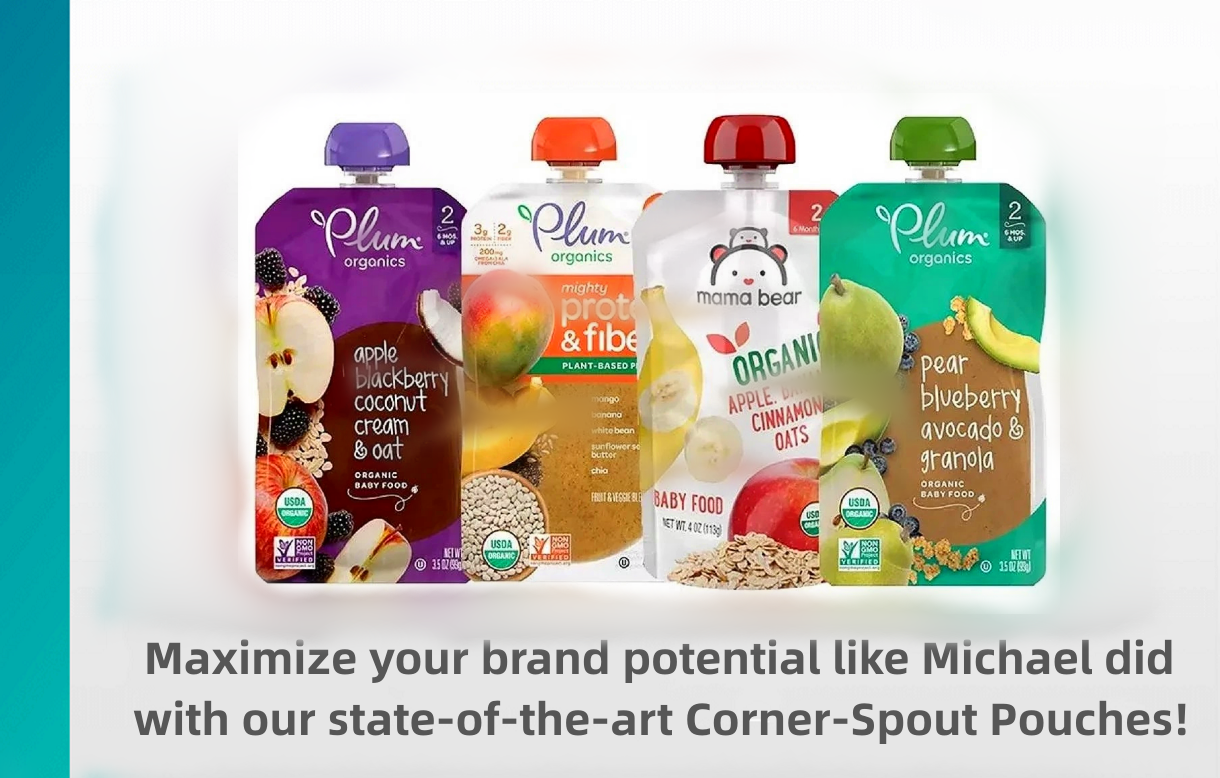

We manufacture billions of pouches & label every year. Our clean room flexible packaging manufacturing environments are built for quality and product safety.

HohuiFlex features advanced rotogravure printing machines in 6, 9, and 12-color options. Each machine is outfitted with computerized color registration and online display systems, ensuring exceptional print quality at low film tension. These machines can handle various flexible and paper materials at high speeds, including select models with electronic axle printing at 200 meters per minute.

HohuiFlex operates 8 of the industry's most advanced blown film machines, including PA/PE 7 Layer Co-ex blown film machines, LDPE blown film machines, and LDPE two-color co-extrusion blown film machines. This diverse array of equipment enables us to quickly adjust production capacity and effectively control costs, meeting the ever-increasing demands of customer orders in terms of both capacity and cost.

HohuiFlex utilizes top-tier dry and extrusion laminators imported from Japan, designed for precision and high-quality lamination film production. Additionally, our European-imported solvent-less laminator offers an eco-friendly packaging solution. As a leader in the packaging industry, we continually invest in innovative technologies.

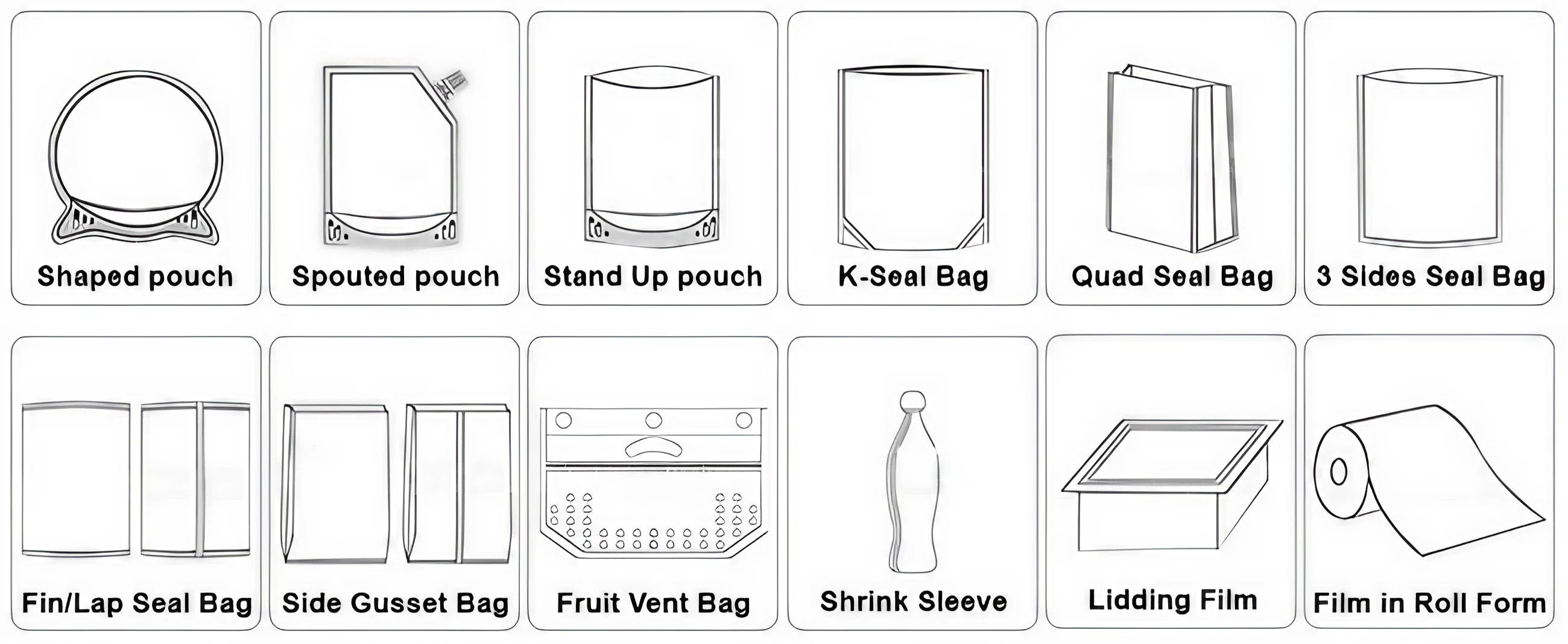

HoHuiFlex has acquired a comprehensive range of pouch manufacturing machines, zipper integration systems, and slitting devices from Japan & Germany. These machines enable the production of sachets and bags with built-in, easy-to-open features using an automated process. Our facilities are fully equipped to meet the diverse pouch requirements of our multinational clients.These advanced pouch-making machines can produce a wide range of bag styles, such as three-side seal pouches with or without zippers, stand-up pouches with reinforced bottoms, four-sided fin sealed bags for optimal product protection, flat-bottom bags for enhanced stability, special-shaped pouches for unique products, and customizable hang hole and tear notch options for consumer convenience.

Industry-leading manufacturing technology and design tool

We believe that any packaging opportunity can be met by applying knowledge and imagination. Our expert engineers and designers have a wealth of flexible packaging experience and can co-create innovative, functional and cost-effective solutions with you. Services include:

Compatibility, vibration, drop and shipment testing

CAD rendering models of parts and components

AutoDesk Moldflow simulation software

3D printing within 24 hours

MOCON oxygen transmission testing

Film, laminate and resin innovation

HoHui continues to lead the way in technological innovations and the design and manufacture of plastic packaging solutions. Through our manufacturing technologies we create custom packaging that successfully meets the most demanding filling and performance requirements while positioning our customers ahead of their competition.

Manufacturing Technologies utilize:

Industrial Design

HoHui's industry recognized, creative team collaborates with customers to quickly develop unique, manufacturable designs that meet new product needs and requirements.

Design solutions are developed rapidly because of our exceptional understanding of the balance between creative design, engineering and manufacturing.

Packaging Design

HoHui’s staff of Design Engineers sets the industry standard for product development including package design and performance. Whether it’s the development of a new design from scratch, optimization of a design developed by a third party or modifications/optimization to a package that’s currently commercial, HoHui’s team of Design Engineers works closely with our customers to deliver industry-leading engineered packaging solutions