At HohuiFlex, we know that wine is more than just a drink – it's a lifestyle. That's why we're dedicated to creating innovative and reliable packaging solutions that protect the quality, taste, and aroma of wine products.

As a leader in the industry, we offer standard and aseptic flexible bag-in-box and pouch solutions to meet all wine needs. Our packaging solutions provide excellent protection against light, oxygen, and other factors that can affect the taste and quality of wine, ensuring that the product stays fresh and delicious from the first pour to the last.

At HohuiFlex, we're committed to sustainability and believe that our packaging solutions play a crucial role in reducing waste and promoting eco-friendliness. That's why our packaging solutions are not only designed to protect the wine but also to be easily recyclable and reusable.

We work closely with our customers to provide customized packaging solutions that meet their unique needs, from small-scale wineries to large-scale operations. With our innovative packaging solutions, we aim to help our customers deliver exceptional wine products that delight consumers around the world

Films For Wine

There are several material structure options available for wine packaging bags, including:

Multi-layer films: Multi-layer films are composed of several layers of different materials, each with a specific function. For example, a typical five-layer film structure for wine packaging may include an outer layer for printing, an inner layer for contact with the wine, a barrier layer for oxygen and moisture resistance, and adhesive layers for bonding the layers together.

Laminates: Laminates are created by bonding two or more materials together. For wine packaging, laminates may consist of a layer of aluminum foil or metalized film, which provides excellent barrier properties, bonded to a layer of polyethylene, which provides strength and durability.

Paper-based materials: Paper-based materials are environmentally friendly and offer a unique aesthetic appeal. For wine packaging, paper bags with an inner layer of polyethylene or other barrier material can be used to provide excellent barrier properties while maintaining the look and feel of paper.

Plastic films: Plastic films such as polyethylene, polypropylene, and polyester are commonly used in wine packaging. These materials offer good barrier properties, strength, and durability, and are available in a range of thicknesses and colors.

Biodegradable materials: Biodegradable materials such as PLA (polylactic acid) and PHA (polyhydroxyalkanoate) offer an eco-friendly alternative to traditional plastic materials. These materials are compostable and can break down naturally over time, reducing their impact on the environment.

Recycled materials: Recycled materials such as post-consumer recycled (PCR) plastic or paper offer an environmentally friendly option for wine packaging. These materials help reduce waste and conserve resources, while still providing the necessary barrier properties and strength required for wine packaging.

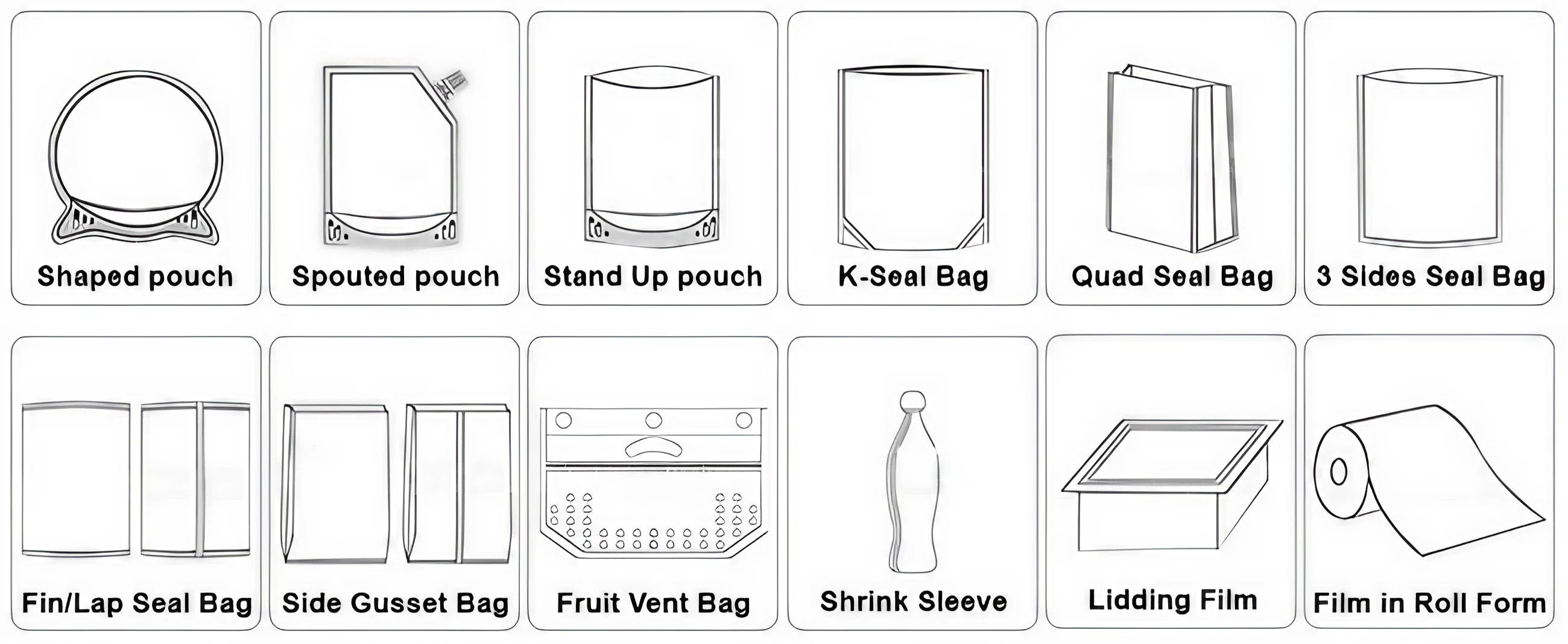

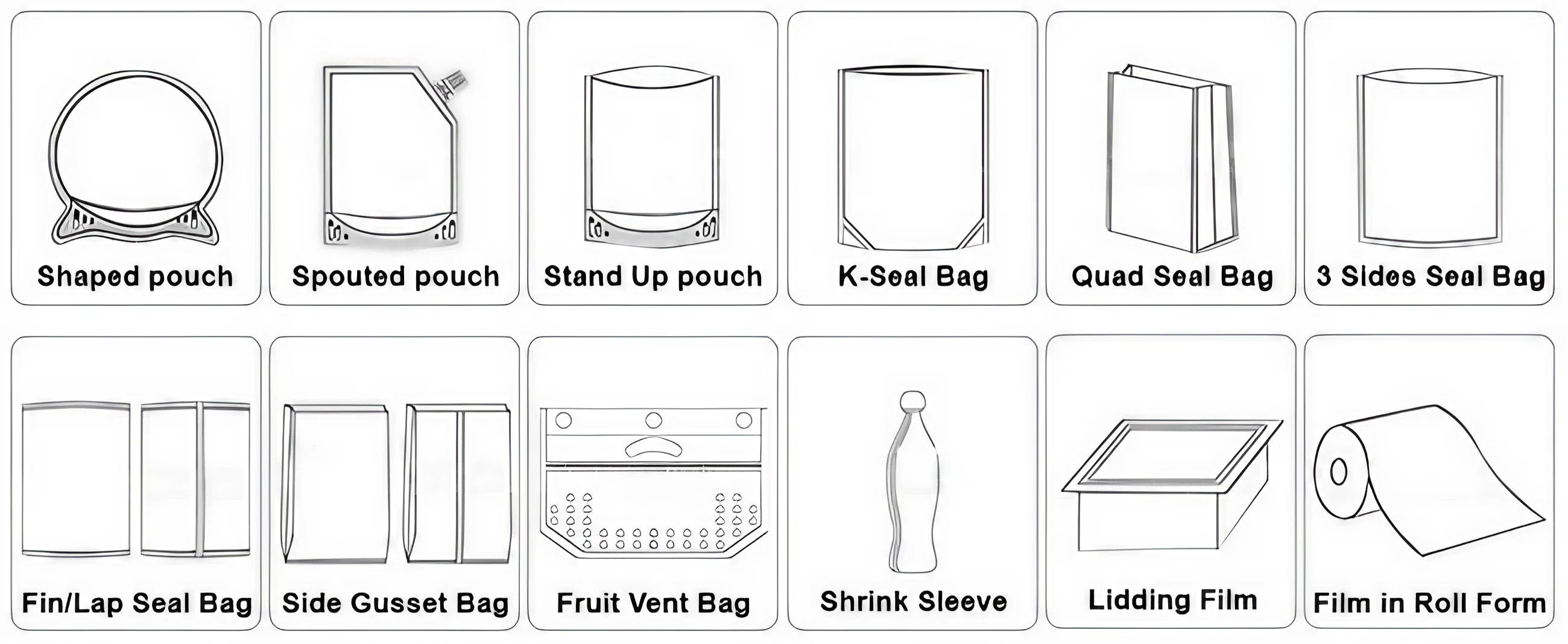

Bags For Wine

There are several bag options available for wine packaging bags, including:

Stand-up pouches: Stand-up pouches are popular for wine packaging because they provide a stable base and can stand upright on store shelves. They are available in a range of sizes and can be fitted with spouts or taps for easy pouring.

Boxed bags: Boxed bags, also known as bag-in-box packaging, are a popular option for wine packaging because they offer excellent protection from light and oxygen. The wine is stored in a bag inside a cardboard box with a tap for easy pouring.

Flat pouches: Flat pouches are a simple, cost-effective option for wine packaging. They are typically made from plastic films or laminates and can be fitted with spouts or zippers for easy pouring and resealing.

Wine totes: Wine totes are a larger option for wine packaging, typically used for transporting multiple bottles of wine. They are typically made from durable materials such as canvas or nylon and have separate compartments for each bottle.

Flexible wine bottles: Flexible wine bottles are a relatively new option for wine packaging that offer the portability and convenience of a pouch with the shape and feel of a traditional wine bottle. They are typically made from multi-layer films or laminates and can be fitted with spouts or resealable caps.

Wine gift bags: Wine gift bags are a decorative option for wine packaging, often used for gift giving. They are typically made from paper or fabric and can be customized with logos, graphics, and other branding elements. They often include handles or other features for easy carrying.

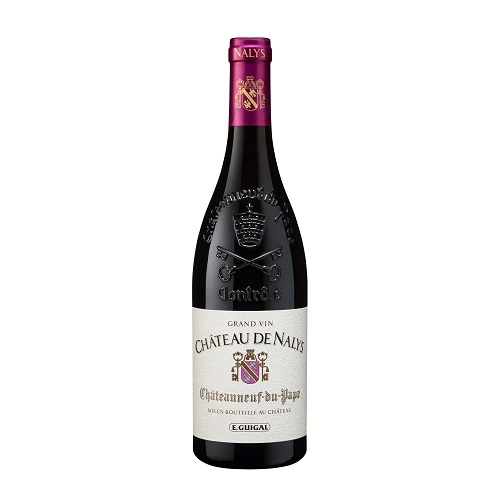

Wine & Spirits Shrink Sleeves

Shrink Sleeves guarantee maximum shelf stand out and lend your product a certain brilliance that catches the eye.

Advantages

Shrink Sleeves visualize the values of the contents of a bottle – class, power, freshness or innovation. Unconventional bottle shapes grab consumer attention, communicate the brand positioning and trigger additional purchase. The Sleeve fits perfectly and gives your product the maximum shelf stand out – brilliance that catches the eye and lets your brand shine.

Benefits of Shrink Sleeves:

PREMIUM LOOK underlines product quality

FLEXIBLE: decoration fits (nearly) all kinds of shapes and materials

RESISTANT to scuffing, humidity and dirt

PROTECTIVE: shield surface of product

COMMENDABLE: no color migration

Wine & Spirits Pressure Sensitive Labels

Unlimited design possibilities, brilliant printing results with gold, silver and metallic effects make PS Labels to become a trendsetter.

Advantages

Pressure Sensitive Labels offer limitless design possibilities that far exceed those of paper wet glue labels: Numerous materials and embellishments are available. Additionally they immensely improve the application process.

Whether paper or synthetic – the choice of substrates is enormous. Besides coated, uncoated, textured and metallized papers there are clear and opaque film options available.

Thanks to state-of-the-art equipment and on-going investments we can offer various printing technologies including gravure, screen, flexo, combination, digital and offset.

Benefits of PSL:

PREMIUM LOOK underlines product quality

NO LIMITS to label design, size and shape

BRILLIANT graphics, outstanding embellishments, elaborate die-cutting, striking hot & cold foil

RESISTANT even in ice water

NO PROBLEM: higher operating efficiency

NO GLUE HANDLING: less cleaning, maintenance & downtime

ALL IN 1: multiple label application (neck, front, back) in one machine pass possible

Wet Glue Wine & Spirits Labels

Wet glue labels for reel-fed production are particularly well-suited and efficient for larger and mass production quantities.

Advantages

Wet glue labels for reel-fed production are particularly well-suited and efficient for larger and mass production quantities.

Wet glue Labels not only present all of the product information in a compact space, but are also the embodiment of your brand identity and crucial to first impressions.

Our finishing techniques provide your label with an exclusive look. The labels can be produced on special substrates like metallized papers, laminated, embossed or with hot-foil stamping, cut or die-cut to any shape.

Wine & Spirit Promotional Labels

The extra piece of “added value” for your packaging. We help to improve your point-of-sale communication!

Advantages

HohuiFlex Promotions Group is an industry-recognized leader in creating successful promotions, interactive games, contests and sweepstakes that spur immediate sales by adding an element of fun to your products.

We offer a variety of exciting extras such as online games with unique codes, Scratch & Win, secure pouch and more. Take advantage of our in-house innovation and expertise to gain strong returns on your promotional investments.

Our Capability

We manufacture billions of pouches & label every year. Our clean room flexible packaging manufacturing environments are built for quality and product safety.

HohuiFlex features advanced rotogravure printing machines in 6, 9, and 12-color options. Each machine is outfitted with computerized color registration and online display systems, ensuring exceptional print quality at low film tension. These machines can handle various flexible and paper materials at high speeds, including select models with electronic axle printing at 200 meters per minute.

HohuiFlex operates 8 of the industry's most advanced blown film machines, including PA/PE 7 Layer Co-ex blown film machines, LDPE blown film machines, and LDPE two-color co-extrusion blown film machines. This diverse array of equipment enables us to quickly adjust production capacity and effectively control costs, meeting the ever-increasing demands of customer orders in terms of both capacity and cost.

HohuiFlex utilizes top-tier dry and extrusion laminators imported from Japan, designed for precision and high-quality lamination film production. Additionally, our European-imported solvent-less laminator offers an eco-friendly packaging solution. As a leader in the packaging industry, we continually invest in innovative technologies.

HoHuiFlex has acquired a comprehensive range of pouch manufacturing machines, zipper integration systems, and slitting devices from Japan & Germany. These machines enable the production of sachets and bags with built-in, easy-to-open features using an automated process. Our facilities are fully equipped to meet the diverse pouch requirements of our multinational clients.These advanced pouch-making machines can produce a wide range of bag styles, such as three-side seal pouches with or without zippers, stand-up pouches with reinforced bottoms, four-sided fin sealed bags for optimal product protection, flat-bottom bags for enhanced stability, special-shaped pouches for unique products, and customizable hang hole and tear notch options for consumer convenience.

Industry-leading manufacturing technology and design tool

We believe that any packaging opportunity can be met by applying knowledge and imagination. Our expert engineers and designers have a wealth of flexible packaging experience and can co-create innovative, functional and cost-effective solutions with you. Services include:

Compatibility, vibration, drop and shipment testing

CAD rendering models of parts and components

AutoDesk Moldflow simulation software

3D printing within 24 hours

MOCON oxygen transmission testing

Film, laminate and resin innovation

HoHui continues to lead the way in technological innovations and the design and manufacture of plastic packaging solutions. Through our manufacturing technologies we create custom packaging that successfully meets the most demanding filling and performance requirements while positioning our customers ahead of their competition.

Manufacturing Technologies utilize:

Industrial Design

HoHui's industry recognized, creative team collaborates with customers to quickly develop unique, manufacturable designs that meet new product needs and requirements.

Design solutions are developed rapidly because of our exceptional understanding of the balance between creative design, engineering and manufacturing.

Packaging Design

HoHui’s staff of Design Engineers sets the industry standard for product development including package design and performance. Whether it’s the development of a new design from scratch, optimization of a design developed by a third party or modifications/optimization to a package that’s currently commercial, HoHui’s team of Design Engineers works closely with our customers to deliver industry-leading engineered packaging solutions