Coatings

Flexible Packaging That Handles Your Coatings Without Melting Down - Chemical-resistant, drop-proof, and custom-built for reactive contents.

At HohuiFlex, we recognize the importance of delivering high-quality coatings products that are not only effective but also safe and easy to use. As a leader in the industry, we've been at the forefront of creating innovative and reliable packaging solutions for coatings products.

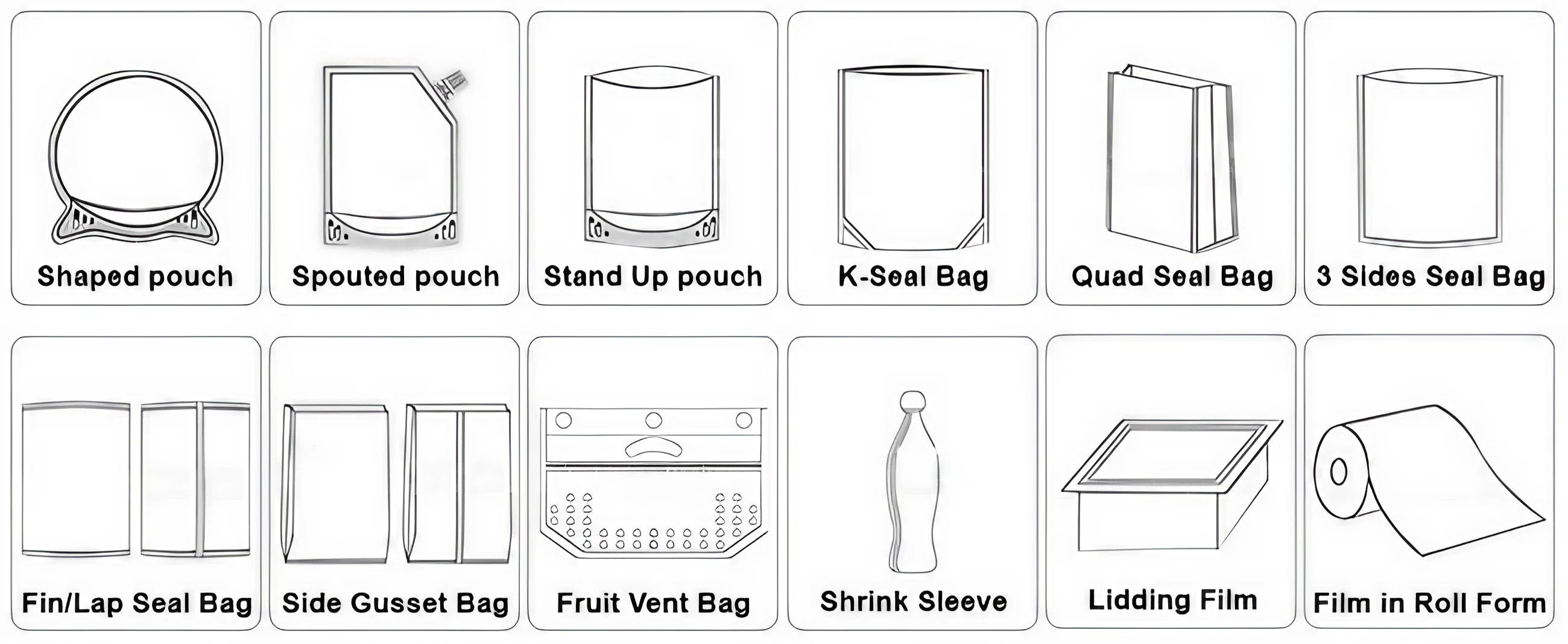

We offer standard and aseptic flexible bag-in-box and pouch solutions that are specifically designed to meet the unique needs of coatings products. Our packaging solutions provide excellent protection against external factors that can affect the quality and performance of coatings, such as air, light, and moisture. Our flexible packaging also offers convenience and ease of use, allowing for precise application and minimizing waste.

At HohuiFlex, we're committed to sustainability and believe that our packaging solutions play a crucial role in reducing waste and promoting eco-friendliness. That's why our packaging solutions are not only designed to protect the coatings but also to be easily recyclable and reusable.

We work closely with our customers to provide customized packaging solutions that meet their unique needs, from small-scale operations to large-scale manufacturing plants. With our innovative packaging solutions, we aim to help our customers deliver exceptional coatings products that exceed industry standards and consumer expectations.

Features of Coatings packaging bags

Coatings packaging bags are often used to store and transport a variety of products, such as food, pharmaceuticals, chemicals, and agricultural products. To ensure that these products remain safe and of high quality during storage and transportation, coatings packaging bags may have certain special requirements. Some of these requirements include:

Bags & films for paint, ink, coatings & varnishes

Bag-in-box packaging tackles the problem of wasted product as the air-tight bag prevents the paint, ink, varnish or coating from drying up for as long as 2 years after opening. This allows users to dispense just the right amount and keep the rest for later use without worrying about a crust forming on the top of the product.

Our robust film structures for paint, coatings and varnishes deliver superior drop protection, flex crack, puncture and tear resistance and long-distance shipping durability. We offer metPET laminate,and biaxially-oriented nylon (BON) laminated structures.

Our bags provide maximum product protection and up to 99% product evacuation.

HohuiFlex offers a wide range of standard bag sizes from 1L to 22L as well as customizable options. Our closed system flexible bags help to prevent unwanted contact with industrial liquids which keeps the users safe.

Bag-in-Box for Coatings

Trust our flexible packaging to keep your coatings secure. Our innovative bag-in-box systems include a wide range of film, fitments, and filling equipment for a total flexible packaging solution engineered to protect your products and those who use them, from fill through final dispensing. We provide:

Pouch Packaging for Coatings

Increase your market appeal by offering coatings in this highly-convenient packaging. Our stand-up, spouted pouches are lightweight, yet built and sealed strong, making them ideal for expanding ecommerce potential of your coating products. Pouches are also ideal for offering smaller amounts for touch-ups, product sampling, or for dosing processes, where precise mixing ratios are critical.

Our Capability

We manufacture billions of pouches & label every year. Our clean room flexible packaging manufacturing environments are built for quality and product safety.

Industry-leading manufacturing technology and design tool

We believe that any packaging opportunity can be met by applying knowledge and imagination. Our expert engineers and designers have a wealth of flexible packaging experience and can co-create innovative, functional and cost-effective solutions with you. Services include:

HoHui continues to lead the way in technological innovations and the design and manufacture of plastic packaging solutions. Through our manufacturing technologies we create custom packaging that successfully meets the most demanding filling and performance requirements while positioning our customers ahead of their competition.

Manufacturing Technologies utilize:

Industrial Design

Packaging Design

HoHui’s staff of Design Engineers sets the industry standard for product development including package design and performance. Whether it’s the development of a new design from scratch, optimization of a design developed by a third party or modifications/optimization to a package that’s currently commercial, HoHui’s team of Design Engineers works closely with our customers to deliver industry-leading engineered packaging solutions

Let’s

connect

From greater sustainability to higher performance, we’re here to deliver what your business needs most.